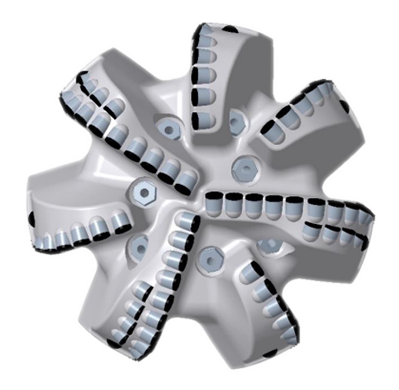

ROLLER CONES BITS

Roller Cones Bits With Sealed Roller Bearings

Ezdan offers both Milled Tooth as well as Tungsten Carbide Insert bits in sealed roller bearing configuration for shallow and low WOB applications. With just a line contact and negligible friction on the high-strength steel rollers, the cones can rotate freely even under low WOB conditions. Silver plated engineered alloy thrust washer and spindle sleeve provides additional bearing surfaces to ensure the cone runs true to the bearing axis, which in turn reduces the radial loads experienced by the seal. The tight tolerances and smooth polished surface finish on the bearing surfaces of the cone and leg ensures the bit durability is maintained for longer run duration. A combination of good bearing and seal design along with temperature resistant grease ensures extended hours on the bearing and lowers the risk of premature pull out.

Roller Cones Bits With Sealed Journal Bearings

Ezdan Journal bearing is designed to handle high WOB values while drilling hard formations for longer durations in challenging applications. The surface contact offered by the silver plated engineered alloy journal along with the thrust washer and the spindle sleeve, enable the bit to withstand high axial and radial loads experienced during the drilling operation. This bearing configuration is available on both Milled Tooth and Tungsten Carbide Insert bits to address varied applications across a wide range of UCS values. The silver acts as a solid lubricant after filling up the micro surface undulations, thereby enhancing the bearing life and the high viscosity temperature resistant grease enters all the nooks and crannies of the bearing in order to keep the frictional heat low and to prolong the bearing hours for longer sections.